Today I returned to the basics skills in Lost Wax Casting. Hand carving the wax.

Today I returned to the basics skills in Lost Wax Casting. Hand carving the wax.

The very first project in the course Shelley (my daughter) and I took was carving a basic ring from wax. The goal was to cast what we designed in silver. We both finished the project and the course with excellent results.

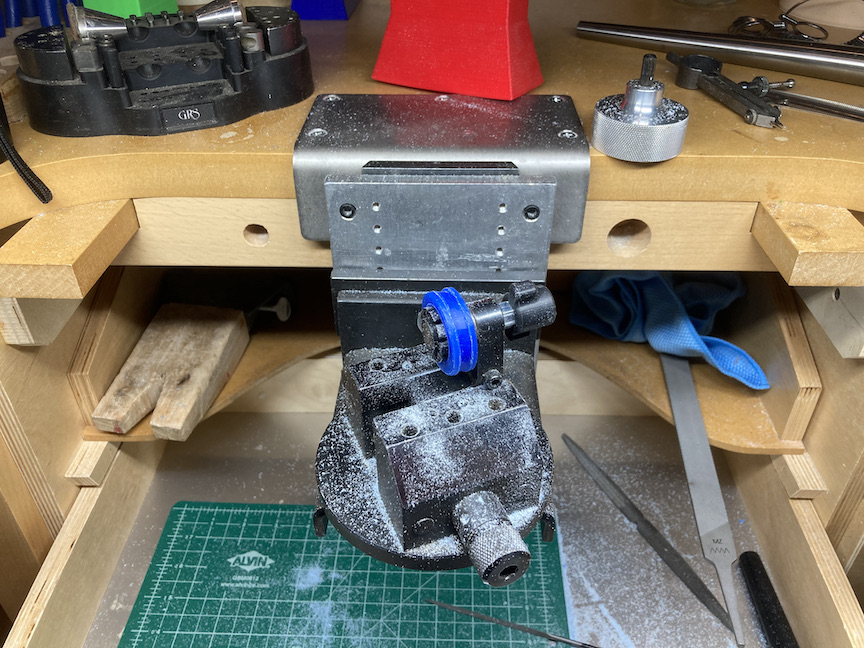

That is where I have returned. I am hand carving a size 12 ring from a block of blue wax. A nice little project.

Nothing special. A simple band design I am just designing “on the fly”. No drawing or pre-conceived plan. Much as I did with my very first project.

Feels good just being creative with the design and working directly with tools on the wax. Truly hand-carved and hand-made. I may use a powered hand tool like a rotary bur or an electrically heated wax pen.

The first training class was to learn to work with all hand tools and no power tools. That’s fine for learning the basics. But for me there is nothing lost by using power hand tools I totally manually control. It is still “hand carving” in my perception.

Other folks are perfectly entitled to a different opinion of “made-by-hand”. Any difference is more emotional than tangible. It’s called being human.

I have no problem with designing with CAD and using CNC to do intricate wax carving. The results are usually far more detailed and accurate. The bulk of the carving is done by CNC but there is still a great deal of hand work to cast and finish a piece.

I never claim “hand carved” unless I do the actual carving through muscle control of my arms and hands.

I never claim “hand carved” unless I do the actual carving through muscle control of my arms and hands.

“Hand made” and “hand carved” are two different terms. I don’t consider them synonymous.

All my work is “made” by my skills which can include power tools. If CNC is only a step in the process of a Lost Wax cast project. I consider the complete piece “personally made”. Portions hand-made and/or hand-carved.

The electrical powered kiln burn-out takes far longer than a CNC run and it too is fully automated with digital temperature control. I don’t watch the kiln for 12 hours adjusting the on/off cycles.

Like this project, I will brag on “hand carved” when true, as that requires special skill. But CAD/CAM from ones own mind and assembled tooling, is also a special skill set. Often producing far more details and accuracy than hand carving.

Hand carving is a special manual skill, involvement and enjoyment as an artist and is never replaced by watching the CNC machine run. Feeling the force of tool removing material is an emotion and special feeling not experienced with full automation. That’s the magic for the artist and can influence a resulting feeling of special ownership of the piece for another person.

There is no correct or best production method for enjoying something personally made. Lost Wax casting; It’s just a process with many steps. It can result is a simple functional cast part or it can be a ”work of art”.

In this post I have bounced between hand made and hand carved. I don’t specialize in either. I have a motto. “Do what you love for those who love what you do.” How I do that is personal.

I don’t love one single process. I do what I love. I learned long ago there is no one “right way” Variation is natural, like the weather. Results will vary and that is a good part of the human experience.

I am adopting a term for my work. Whatever process I enjoying using, the final result will be something “personally designed and crafted”. Read the fine print if I detail special hand-steps in the process.